In the consumer food and beverage sector, there is an increasing demand for higher production output, global expansion, and tighter quality control. Facilities involved in the manufacturing and packaging of food and beverage products are implementing processes to enhance quality, efficiency, and yield. However, without precise measurement data, these efforts can lead to waste and inefficiencies.

The food processing automation market is experiencing robust growth. A critical need for efficiency, traceability, and waste reduction drives this rapid expansion. The industry is moving toward real-time, data-driven systems, from robotics and process monitoring to final packaging check-weighing.

Tailored Solutions for Food Production Optimization

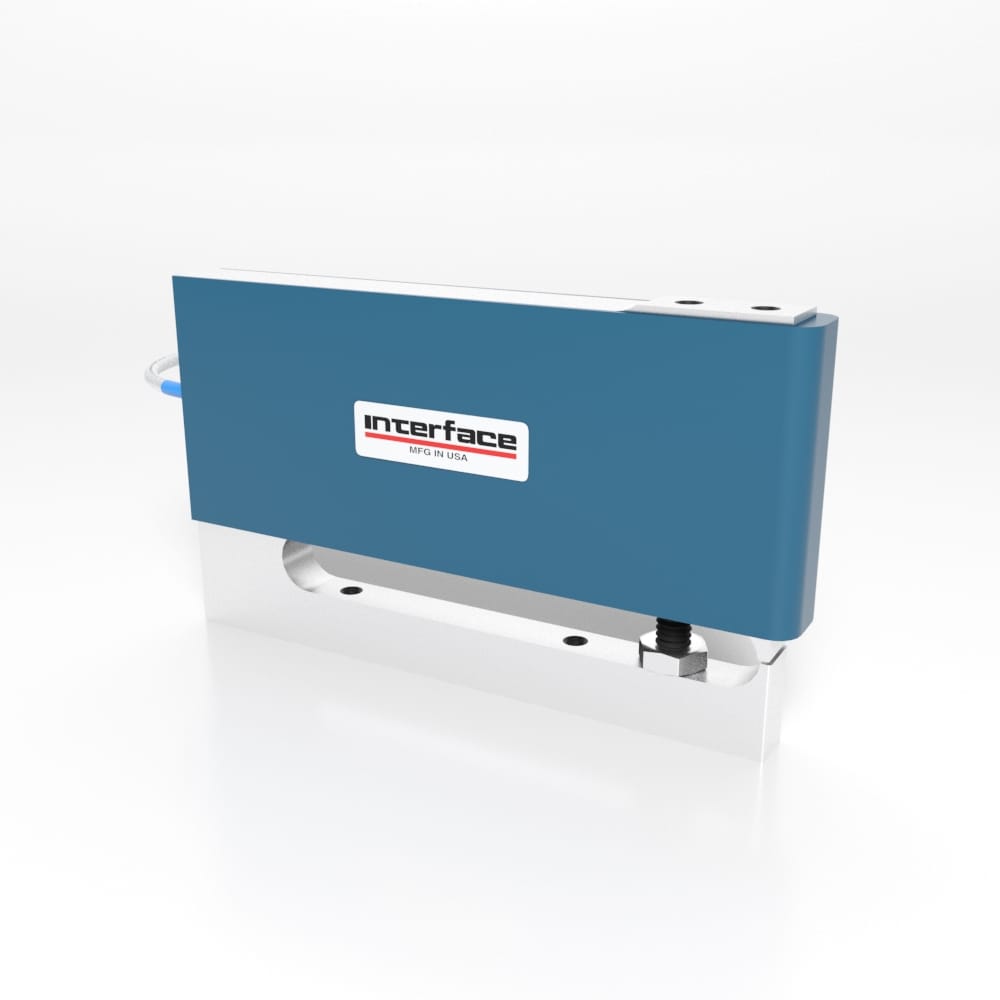

At Interface, we help engineers and manufacturers optimize the entire food and beverage production journey through advanced force measurement solutions. Our sensor technologies provide the critical data needed to minimize inefficiencies and reduce product giveaways. By monitoring the “health” of your production line, our load cells can help predict maintenance needs, preventing costly downtime and material spoilage.

The versatility of Interface sensor technologies allows facilities to achieve the highest standards of condition, consistency, and productivity for canning, bottling, and packaging.

Food and Beverage Applications for Interface Measurement Solutions

- Harvesting Equipment

- Food Handling, Picking and Sorting

- Weighing and Yield Management

- Silo Dispensing and Tank Monitoring

- Processing Machines, Mixers, and Cutters

- Production Line

- Robotics

- Check Weighing

- Filling Machines

- Capping & Sealing

- Conveyor Monitoring and Maintenance

- Palletizing and Storage

- Packaging

Interface provides reliable, accurate, and rugged sensor technologies suitable for highly regulated environments, including washdown zones, ensuring product safety and line efficiency.

Whether you need to integrate a sensor into a new piece of equipment, retrofit production hardware to provide measurement data, or research ways to use force measurements in submersible or low-temperature environments, we can help you find the best product to meet your specific requirements.

Interface Products Used in Food & Beverage

- LowProfile Load Cells

- Platform Scale Load Cells

- Miniature Beam Load Cells

- Load Button Load Cells

- PBLC Pillow Block Load Bearing Load Cells

- Torque Transducers

- Multi-Axis Sensors

- Load Pins and Tension Links

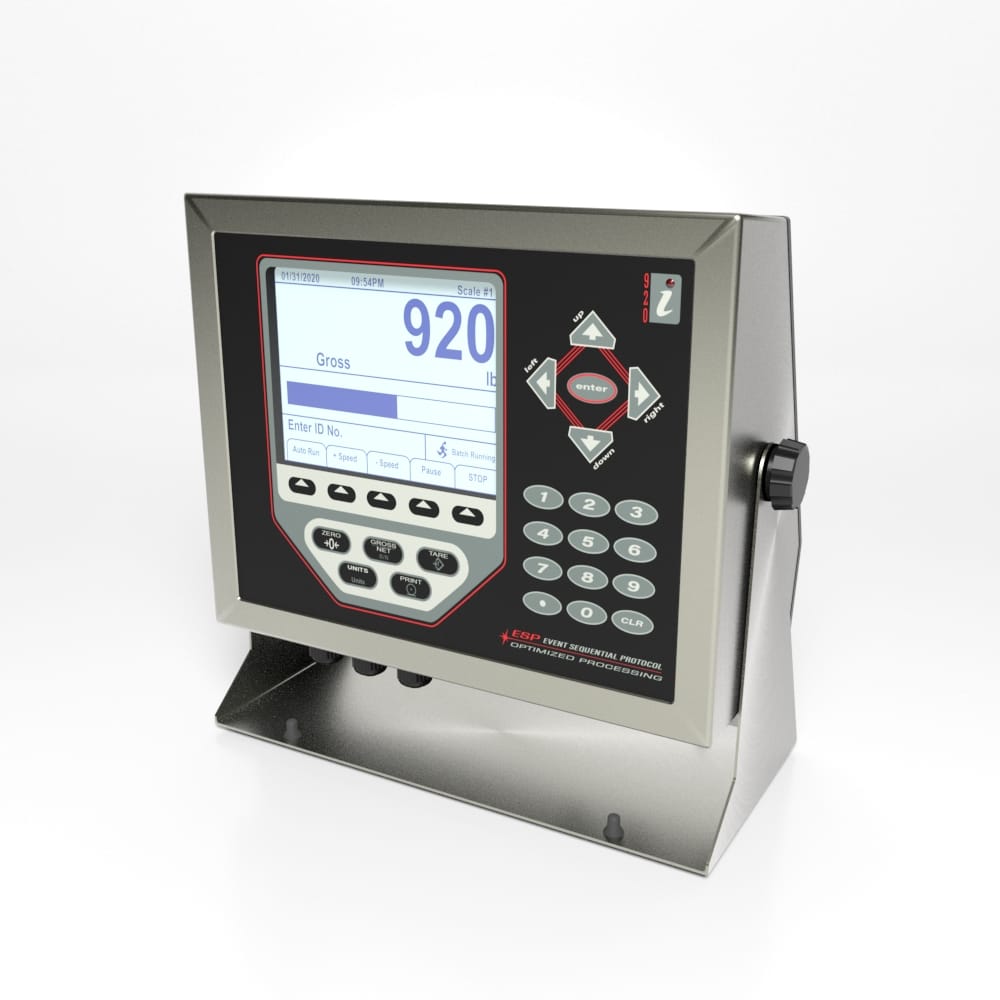

- Instrumentation

- DAQ

- Complete Systems

- WTS Wireless Telemetry Systems

Efficiency equals agility. With solutions like our WTS Wireless Telemetry Systems, facility managers can gather real-time data from multiple points on the production line, from bin weighing to robotic arm operation, without the mess of cables.

Interface force measurement solutions are used by production line engineers, machine builders, equipment manufacturers, and OEMs, as well as in equipment and tool suppliers. Interface force measurement solutions are used in all aspects of food production, including agricultural equipment, weighing scales, industrial automation robotics, and lifting machines used to transport consumer goods.

Interface collaborates with our customers to provide the right measurement solution to help ensure your product reaches the table safely, efficiently, and cost-effectively.

Additional Resources

Commercial Food Processing

Food and Beverage Conveyor Belt

Force Measurement for Efficiency in Food Processing and Packaging

Load Cells for Smarter and More Efficient Weighing

Vertical Farming for Sustainable Food Production on Earth and Beyond

Interface Helps to Move Agriculture Innovation Forward

Chicken Weighing

Fruit Weighing

Interface Manufacturing and Production Solutions

Water Bottle Dispensing and Weighing

Water Bottle Dispensing and Weighing

Raw Signals to Intelligent Force Sensing

/in Blog /by Jamie GlassInterface load cells, multi-axis sensors, and data acquisition systems are providing data for integrating artificial intelligence into force measurement systems. This represents a significant leap forward in precision, responsiveness, and reliability for these data use cases. The rise in use of strain gage outputs for AI is on the rise. The quality of the sensor is critical for these applications, and this is why Interface products are valuable for advanced analytics.

The Testing Behind Your Favorite Gifts

/in Blog /by Jamie GlassInterface offers a range of sensors for precise testing and force measurement across popular products such as gaming equipment, sports gear, electronics, scooters, and smartwatches. We take pride in ensuring these favorite gifts are safe, reliable, and durable well beyond the holiday season.

Measuring Control in Animatronics and Entertainment Robotics

/in Blog /by Jamie GlassAnimatronics is a dynamic field of entertainment that fuses puppetry, anatomy, mechatronics, and robotics. Behind the expansion of animatronics and entertainment robotics is the increasing demand for immersive, interactive experiences supported through high-accuracy force, torque, and weight measurements using Interface measurement solutions and sensor technologies.

Beyond the Obvious Forces of Product Testing

/in Blog /by Jamie GlassTrue precision in testing requires developing a mindset that embraces failure, diagnoses invisible errors, and knows that the best results come from understanding that every component, connection, and procedure is part of a complex system that demands relentless attention. Interface provides high-accuracy test and measurement products, including load cells, for testing labs.

Fatigue-Rated Load Cells 101

/in 101 Series, Blog /by Jamie GlassInterface Fatigue-Rated Load Cells are specialized force sensors engineered to accurately measure loads over an extended operational life exceeding 100 million fully reversed, full-capacity loading cycles, crucial for durability and long-term performance testing. Their design emphasizes reduced stress levels, optimized geometries, and robust construction to prevent fatigue failure under repetitive loading.

Smart Food Packaging Uses Force Measurement

/in Blog /by Jamie GlassInterface force measurement technologies are helping to transform the food packaging industry with greater precision and reduced waste. Interface offers sensor solutions to automate and regulate every packaging stage, from rigorous packaging material tests to precise force measurements for filling, sealing, and distributing food products.

Precision Prototyping Uses Force Measurement for Design Validation

/in Blog /by Jamie GlassInterface load cells, torque transducers, and multi-axis sensors equip engineers with essential data for design validation and optimization for precise prototyping. Whether for testing alone or integration, both scenarios for sensors measuring physical parameters like force, torque, and weight provide insights into the prototype’s performance and behavior under various conditions. Industries use proof-of-concepts, production prototypes, and functional prototypes that require precise measurements to validate the final design.

Interface Top Industry and Application Insights of 2024

/in Blog /by Jamie GlassExplore Interface’s top industry solutions and applications using force measurement products. Discover medical, aerospace, automation, automotive, energy, and other industry test and measurement applications. Find inspiration and answers for your specific needs using Interface load cells, torque transducers, and instrumentation.

Fun Facts About Force Measurement to Wrap Up 2024

/in Blog /by Jamie GlassInterface fun facts demonstrate how force measurement constantly evolves and contributes to breakthroughs in various fields, from measuring rocket thrust to monitoring athlete’s performance. It’s a testament to the ingenuity of engineers and scientists who continue to find new and innovative ways to utilize this fundamental measurement principle.

Integrated Measurement Solutions Elevate Design and Enhance Functionality

/in Blog /by Jamie GlassInterface, a pioneer in load cell design, supports innovation by offering integrated measurement solutions that ensure the safety and reliability of machines, products, and processes in sectors including aerospace, energy, medical and healthcare, automotive, manufacturing, and industrial automation. Our sensor technologies are seamlessly integrated into diverse products and machines, from lifting equipment to consumer goods. This adaptability ensures that our solutions can be tailored to your unique requirements.